Services

7 Stage Process

End to end service for quality results

There are several stages we go through to complete your powder coating order. They are Pre Treatment, Powder Coating, Curing and all of these phases are carried out in line with our stringent quality assurance procedures.

Masking

At Custom Wytelyne we take a great deal of time and effort in choosing the correct method of masking your product needs.

Factors we take into account:

- Price

- Quality

- Ease of removal

- Workers efficiency

- Volumes

We offer manual masking to die cut moulded rubber masking solutions.

Jigs and loading of components

We have many years experience in the design of jigs to hold your components for coating.

We take into account the volumes you require, cost and ease of loading.

We work hard hand in hand with our jig manufacturer to achieve the most cost effective formula in today’s changing market place.

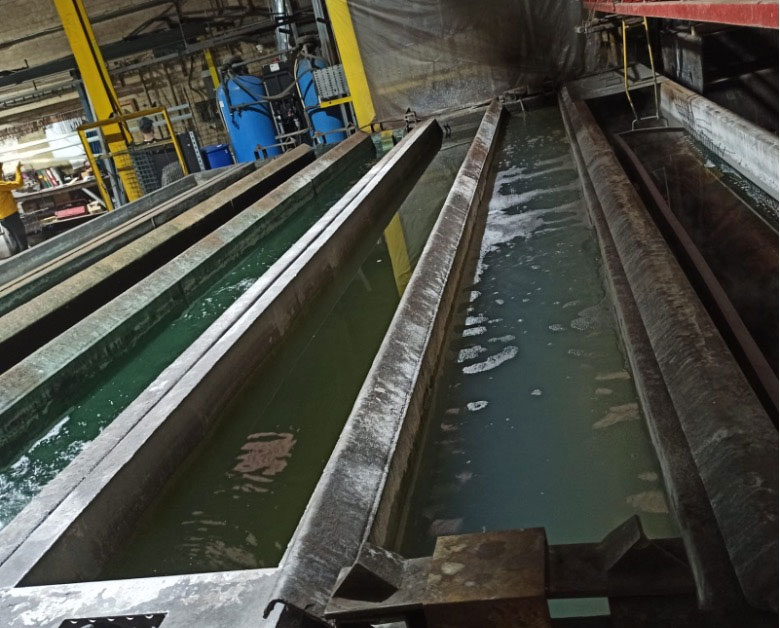

Pre-treatment

Thorough pre-treatment is essential to ensure a high quality, long lasting and durable finish. To begin we prepare the item and offer three types of pre-treatment according to the base materials, it’s condition and the type of finish required.

Powder coating

We powder coat your items using the latest equipment available to ensure quality every time. There are several finishes available and two different applications that we use.

Curing

We use several different solutions to cure the powder coated item, including radiant heat, camel back ovens and box ovens.

Packaging and Delivery

Our optional packaging and delivery service ensures your items are transported to you safely.

Get a quote today!

If you want great service, powder coating reliability and guaranteed quality at competitive prices, contact us now to discuss your needs with one of our friendly, professional team.

Contact us